- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Thickness: | |

|---|---|

| Outer Diameter: | |

| Material: | |

| Payment terms: | |

| Package: | |

| Sample: | |

| Application: | |

| Availability: | |

| Quantity: | |

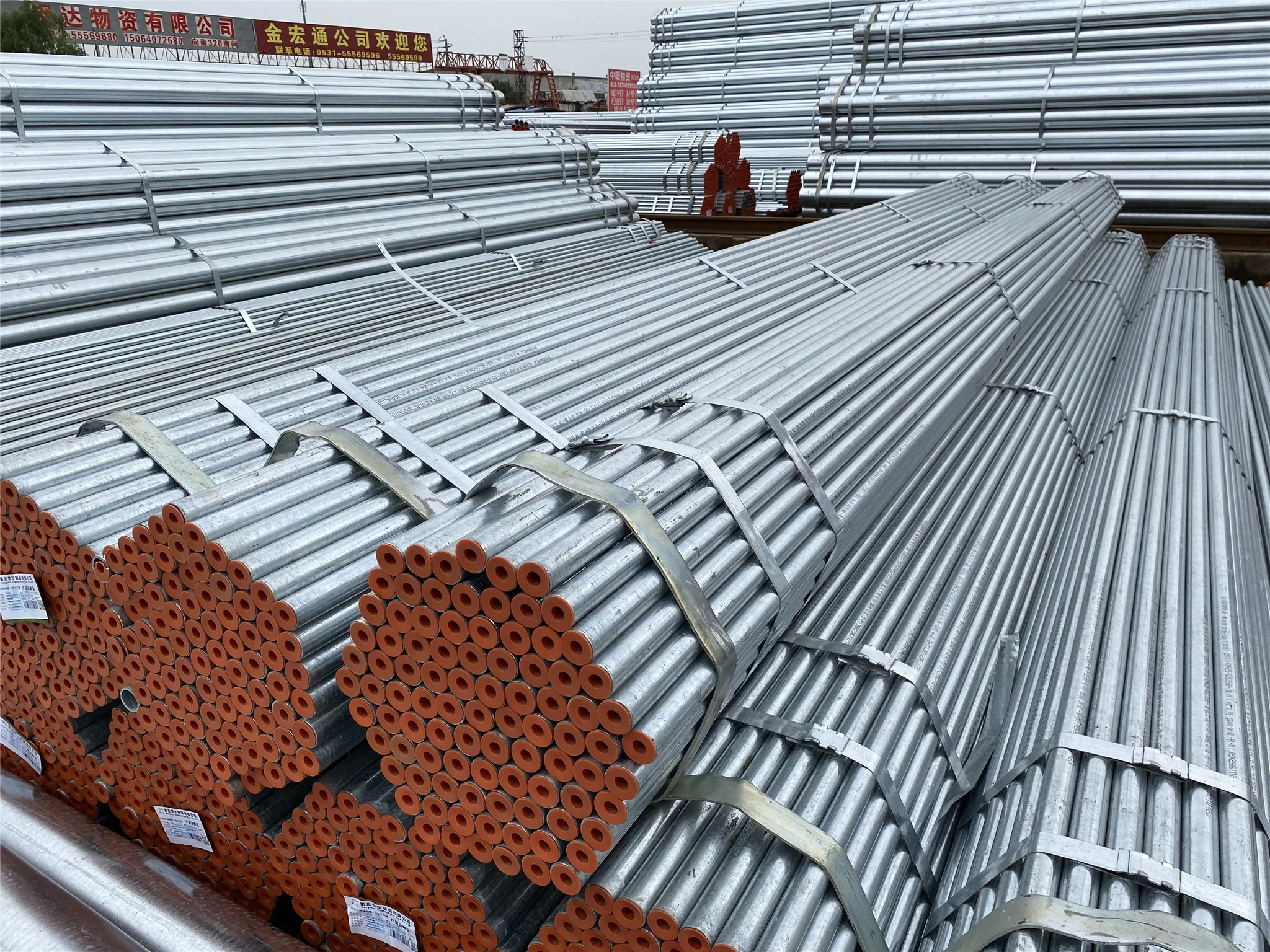

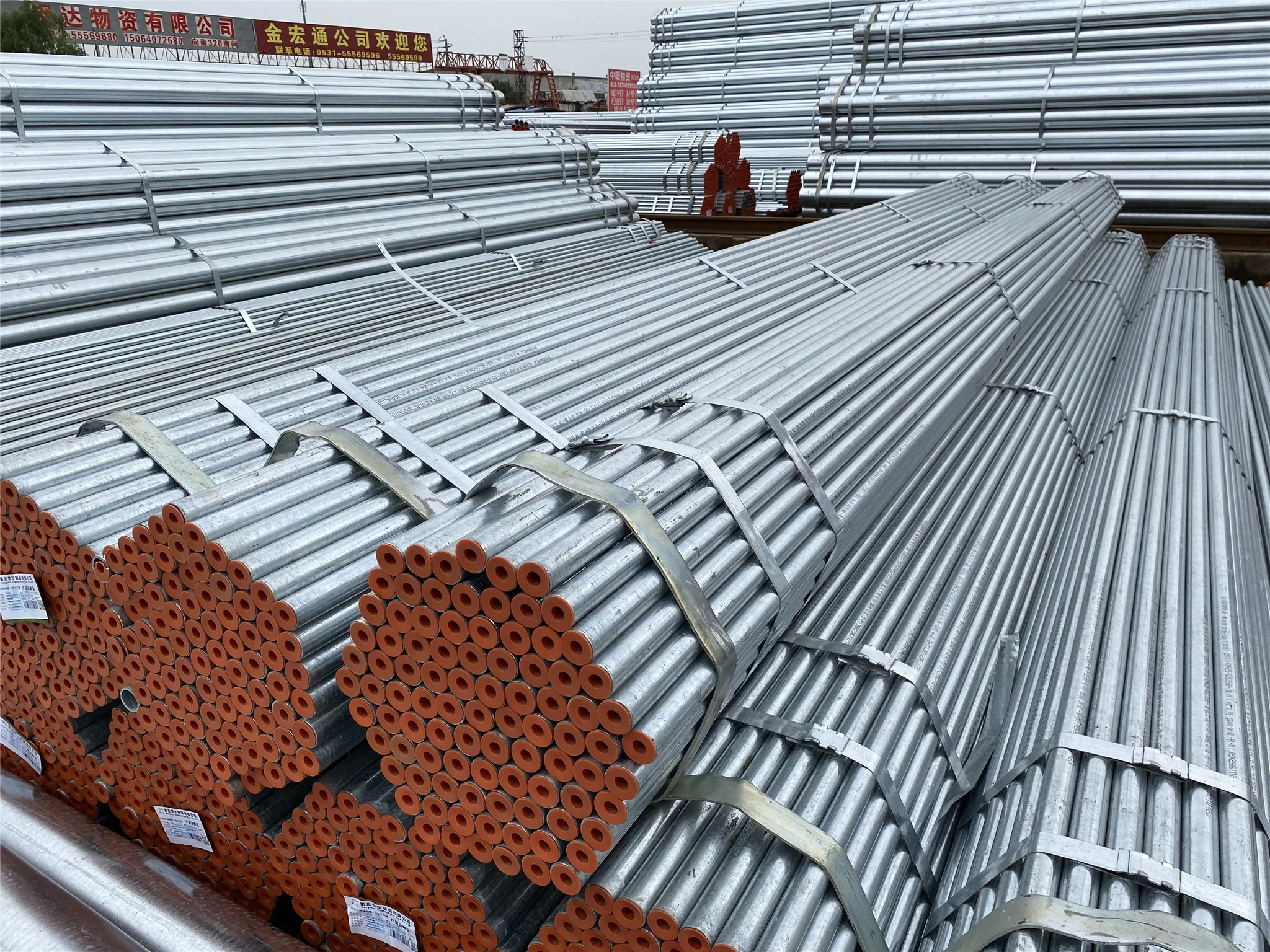

Steel Round Pipe/Tube

| Product Name | Seamless steel pipe with low price for construction |

| Material | Q345 |

| Shape | Round Shape |

| Standard | ASTM, BS, DIN, GB, JIS |

| Grade | SUS201, SUS304, SUS316, A2-70, A2-80, A4-80, 4.8 6.8 8.8 10.9 12.9 |

| Usage | Construction Structure |

SPECIFICATION TABLE

| DN | OD | ASTM A53 / API 5L | BS1387 / EN10255 | |||||

| SCH10S | STD SCH40 | SCH80 | Light | Medium | Heavy | |||

| MM | INCH | MM | MM | MM | MM | MM | MM | |

| 15 | 21.3 | 1/2" | 2.11 | 2.77 | 3.73 | 2 | 2.6 | - |

| 20 | 26.7 | 3/4" | 2.11 | 2.87 | 3.91 | 2.3 | 2.6 | 3.2 |

| 25 | 33.4 | 1" | 2.77 | 3.38 | 4.55 | 2.6 | 3.2 | 4 |

| 32 | 42.2 | 1-1/4" | 2.77 | 3.56 | 4.85 | 2.6 | 3.2 | 4 |

| 40 | 48.3 | 1-1/2" | 2.77 | 3.68 | 5.08 | 2.9 | 3.2 | 4 |

| 50 | 60.3 | 2" | 2.77 | 3.91 | 5.54 | 2.9 | 3.6 | 4.5 |

| 65 | 73 | 2-1/2" | 3.05 | 5.16 | 7.01 | 3.2 | 3.6 | 4.5 |

| 80 | 88.9 | 3" | 3.05 | 5.49 | 7.62 | 3.2 | 4 | 5.0 |

| 90 | 101.6 | 3-1/2" | 3.05 | 5.74 | 8.08 | |||

| 100 | 114.3 | 4" | 3.05 | 6.02 | 8.56 | 3.6 | 4.5 | 5.4 |

| 125 | 141.3 | 5" | 3.4 | 6.55 | 9.53 | 5.0 | 5.4 | |

| 150 | 168.3 | 6" | 3.4 | 7.11 | 10.97 | 5.0 | 5.4 | |

| 200 | 219.1 | 8" | 3.76 | 8.18 | 12.7 | |||

| 250 | 273.1 | 10" | 4.19 | 9.27 | 15.09 | |||

We produce high-grade seamless aluminum tubing

According to the processing method is divided into extrusion seamless aluminum tube, cold drawn precision seamless aluminum tube,rolling seamless aluminum tube. Among them, the cold drawing precision of seamless aluminum tube with high precision, good surface

quality.

The Main Process of Seamless Aluminum Tube:

Seamless aluminum tubes are produced by piercing extrusion, while conventional aluminum tubes are usually extruded by a combined

die. Aluminum Alloy seamless tube production principle and process production using the short rod, high temperature, slow speed

extrusion process, especially to control the “three temperature”, aluminum rod extrusion cylinder, and die to keep clean, aging time and temperature are adjusted according to the thickness and diameter of the wall.

Cold Drawn seamless aluminum Tube (pipe):

In the beginning, a drawn structural tube goes through the same process as an extruded tube. However, where an extruded tube is cooled after it is forced through the die, the drawn tube is sent through a second die. This process is called cold drawing or cold working, and it is here that the final dimensions of the product are determined. A drawn tube is just as suitable for transporting gases or liquids under pressure as a seamless extruded tube.a seamless extruded tube is brought to final size by drawing through a die. Closer size tolerances and thinner wall thicknesses

than that of extruded tube are available.

| Product Name | Seamless steel pipe with low price for construction |

| Material | Q345 |

| Shape | Round Shape |

| Standard | ASTM, BS, DIN, GB, JIS |

| Grade | SUS201, SUS304, SUS316, A2-70, A2-80, A4-80, 4.8 6.8 8.8 10.9 12.9 |

| Usage | Construction Structure |

SPECIFICATION TABLE

| DN | OD | ASTM A53 / API 5L | BS1387 / EN10255 | |||||

| SCH10S | STD SCH40 | SCH80 | Light | Medium | Heavy | |||

| MM | INCH | MM | MM | MM | MM | MM | MM | |

| 15 | 21.3 | 1/2" | 2.11 | 2.77 | 3.73 | 2 | 2.6 | - |

| 20 | 26.7 | 3/4" | 2.11 | 2.87 | 3.91 | 2.3 | 2.6 | 3.2 |

| 25 | 33.4 | 1" | 2.77 | 3.38 | 4.55 | 2.6 | 3.2 | 4 |

| 32 | 42.2 | 1-1/4" | 2.77 | 3.56 | 4.85 | 2.6 | 3.2 | 4 |

| 40 | 48.3 | 1-1/2" | 2.77 | 3.68 | 5.08 | 2.9 | 3.2 | 4 |

| 50 | 60.3 | 2" | 2.77 | 3.91 | 5.54 | 2.9 | 3.6 | 4.5 |

| 65 | 73 | 2-1/2" | 3.05 | 5.16 | 7.01 | 3.2 | 3.6 | 4.5 |

| 80 | 88.9 | 3" | 3.05 | 5.49 | 7.62 | 3.2 | 4 | 5.0 |

| 90 | 101.6 | 3-1/2" | 3.05 | 5.74 | 8.08 | |||

| 100 | 114.3 | 4" | 3.05 | 6.02 | 8.56 | 3.6 | 4.5 | 5.4 |

| 125 | 141.3 | 5" | 3.4 | 6.55 | 9.53 | 5.0 | 5.4 | |

| 150 | 168.3 | 6" | 3.4 | 7.11 | 10.97 | 5.0 | 5.4 | |

| 200 | 219.1 | 8" | 3.76 | 8.18 | 12.7 | |||

| 250 | 273.1 | 10" | 4.19 | 9.27 | 15.09 | |||

We produce high-grade seamless aluminum tubing

According to the processing method is divided into extrusion seamless aluminum tube, cold drawn precision seamless aluminum tube,rolling seamless aluminum tube. Among them, the cold drawing precision of seamless aluminum tube with high precision, good surface

quality.

The Main Process of Seamless Aluminum Tube:

Seamless aluminum tubes are produced by piercing extrusion, while conventional aluminum tubes are usually extruded by a combined

die. Aluminum Alloy seamless tube production principle and process production using the short rod, high temperature, slow speed

extrusion process, especially to control the “three temperature”, aluminum rod extrusion cylinder, and die to keep clean, aging time and temperature are adjusted according to the thickness and diameter of the wall.

Cold Drawn seamless aluminum Tube (pipe):

In the beginning, a drawn structural tube goes through the same process as an extruded tube. However, where an extruded tube is cooled after it is forced through the die, the drawn tube is sent through a second die. This process is called cold drawing or cold working, and it is here that the final dimensions of the product are determined. A drawn tube is just as suitable for transporting gases or liquids under pressure as a seamless extruded tube.a seamless extruded tube is brought to final size by drawing through a die. Closer size tolerances and thinner wall thicknesses

than that of extruded tube are available.