- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Thickness: | |

|---|---|

| Tolerance: | |

| Steel Grade: | |

| Surface Finish: | |

| Width: | |

| Application: | |

| Availability: | |

| Quantity: | |

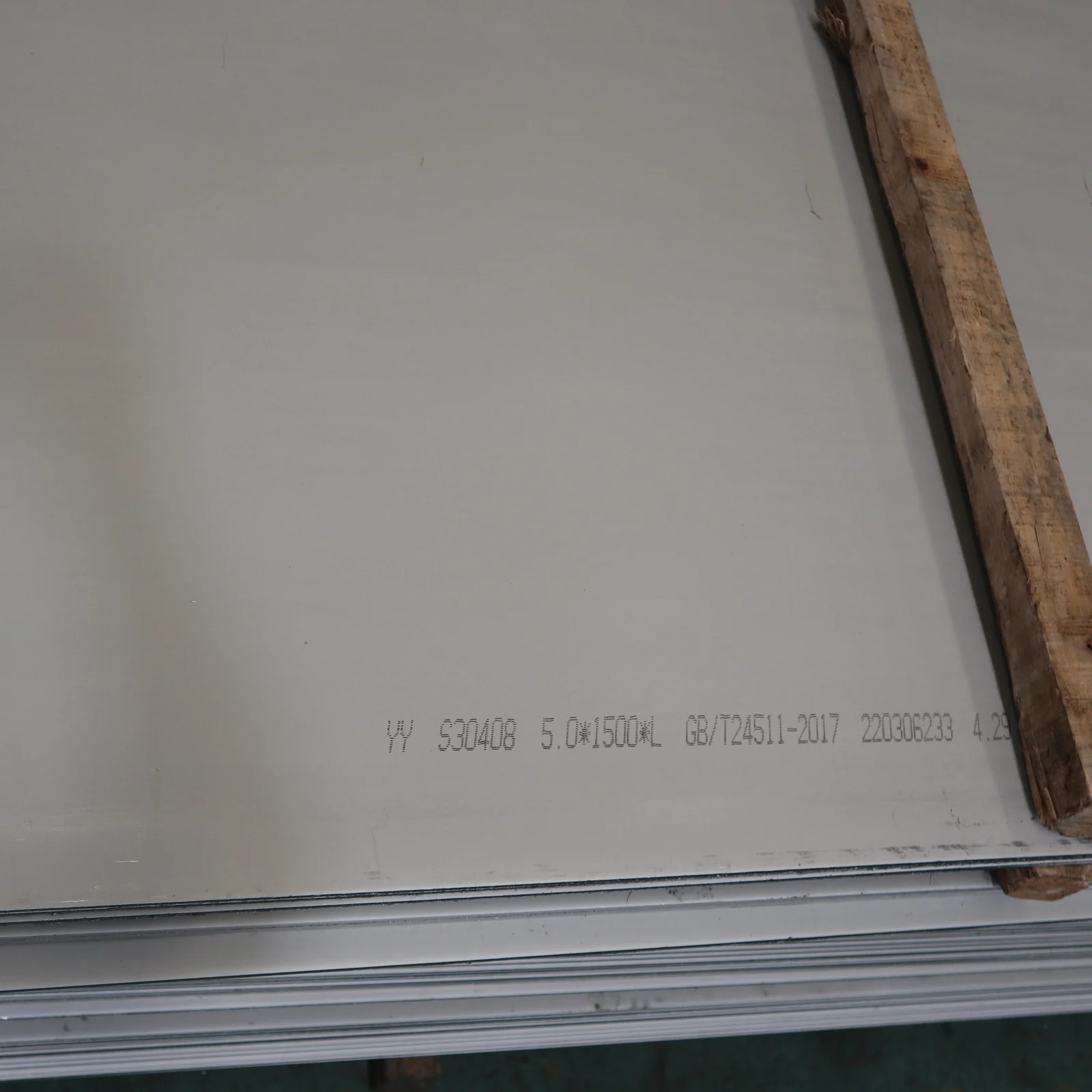

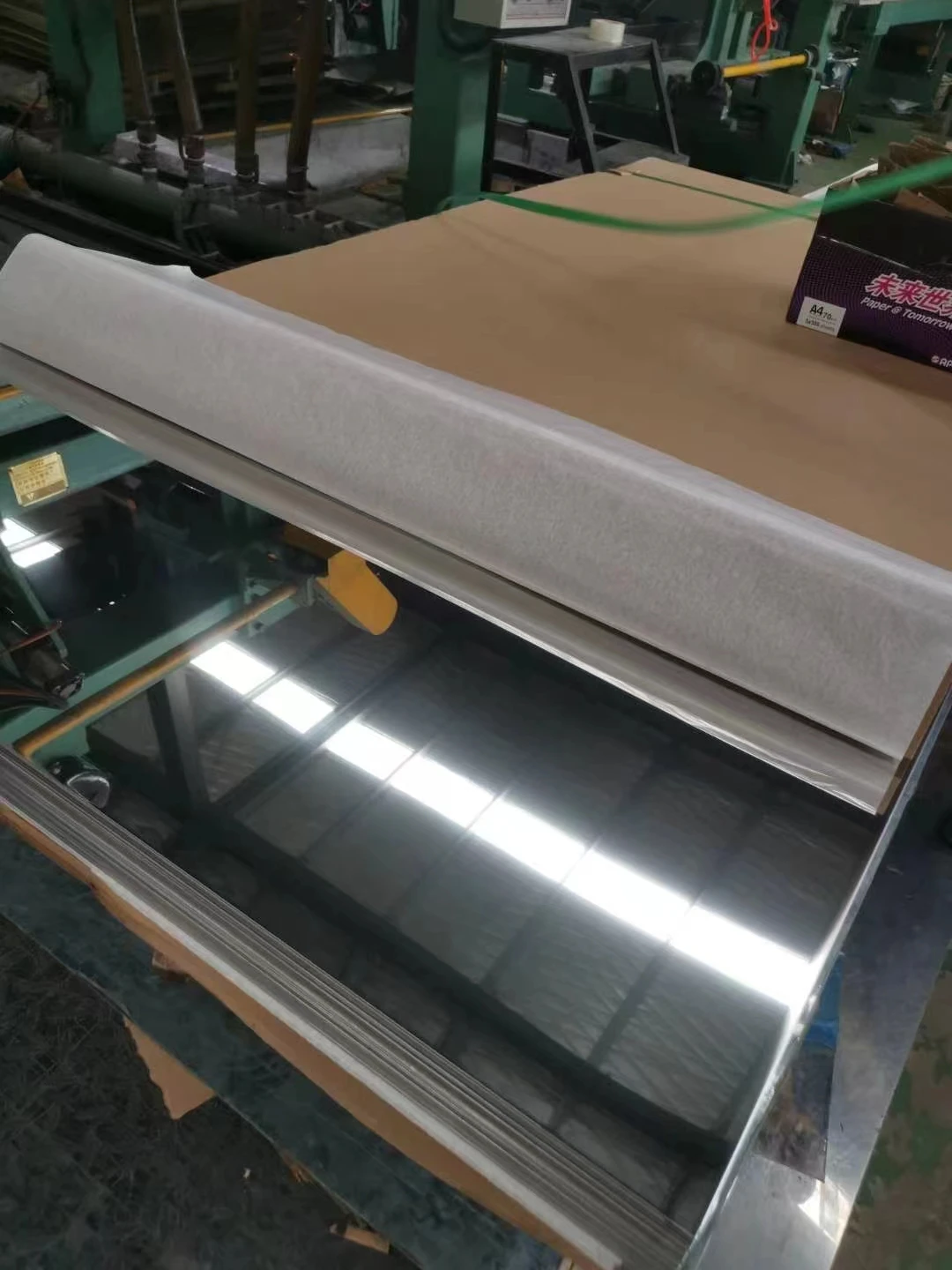

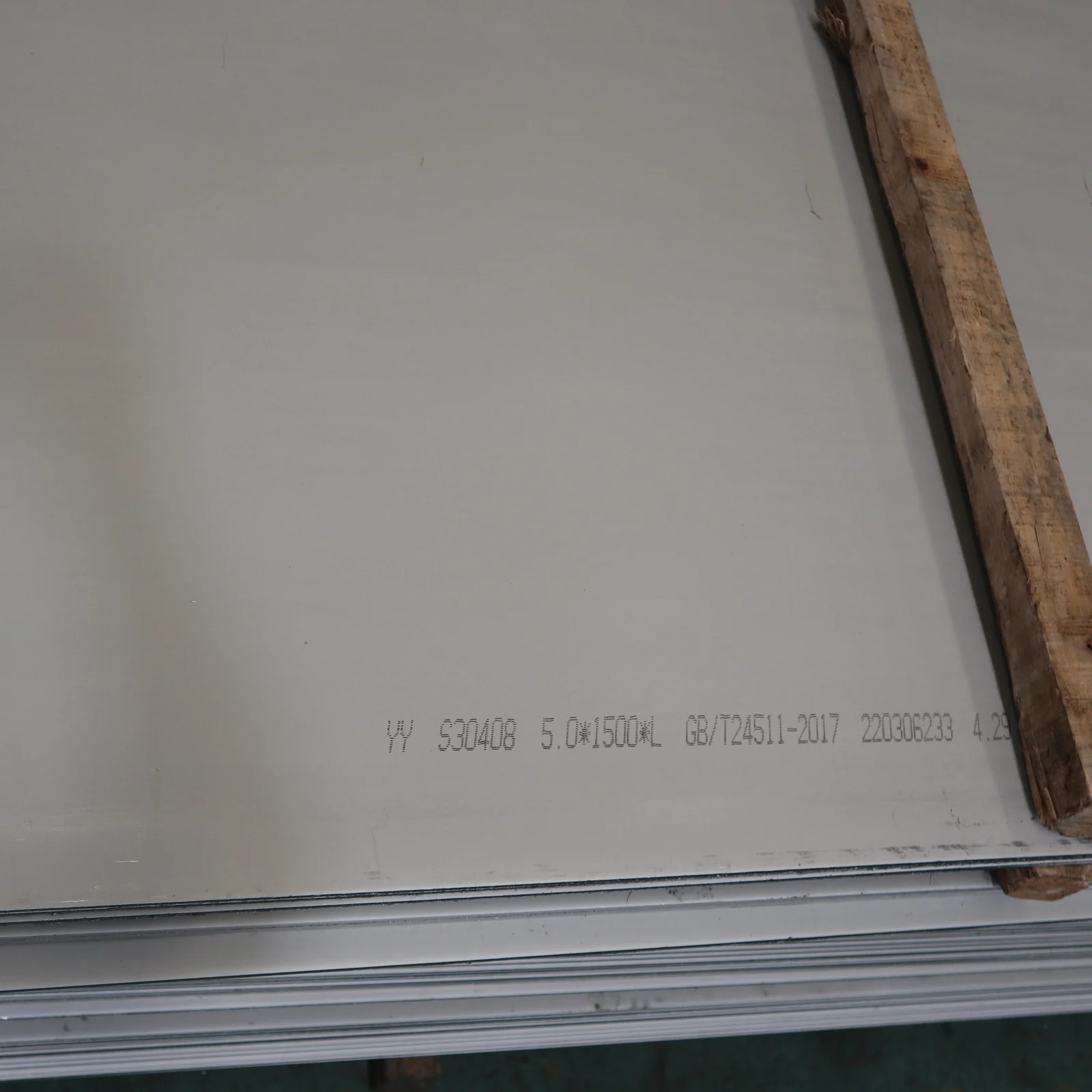

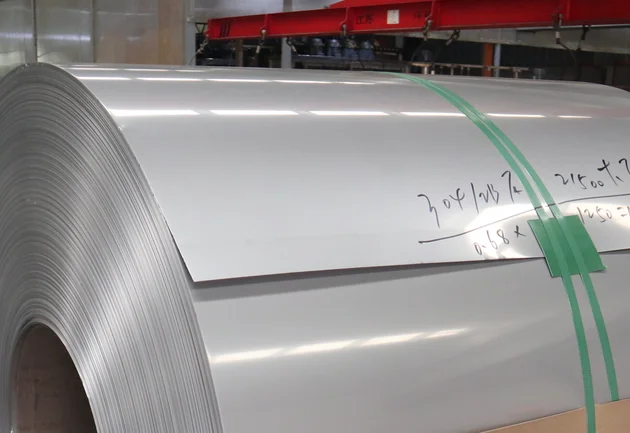

The ASME A240 304N 304L Stainless Steel Sheet/Plate is a high-quality, versatile material widely used in various industries. Known for its smooth surface, corrosion resistance, and excellent weldability, it is a critical component in modern industrial manufacturing. This stainless steel sheet is ideal for architectural, automotive, shipbuilding, engineering, construction, and infrastructure applications. Thanks to its ability to withstand harsh environments, it is used in a variety of industrial, marine, and metalworking projects.

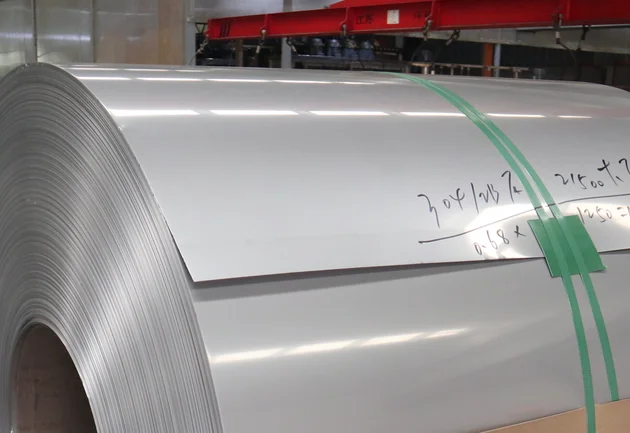

Manufactured according to the ASME A240 standard, the 304N and 304L types of stainless steel sheets exhibit the best features of austenitic stainless steel, offering high toughness, plasticity, and weldability. These sheets are available in various finishes such as polished, brushed, etched, powder-coated, and more, offering versatility for both functional and decorative uses. Whether you need custom-sized, oversized, or standard-sized stainless steel plates, we can deliver tailored solutions for your requirements.

Product Advantage

The ASME A240 304N 304L Stainless Steel Sheet/Plate boasts several advantages that make it the go-to material for a wide range of applications:

Superior Corrosion Resistance:

The 304N and 304L types contain around 18% chromium and 8% nickel, which provide exceptional resistance to corrosion, particularly in environments exposed to moisture or harsh chemicals. This corrosion resistance makes it perfect for marine and industrial environments, where the material is exposed to challenging conditions.

Excellent Weldability:

With high weldability, this stainless steel plate is ideal for industries requiring strong and long-lasting welded connections, including shipbuilding, engineering, and metalworking.

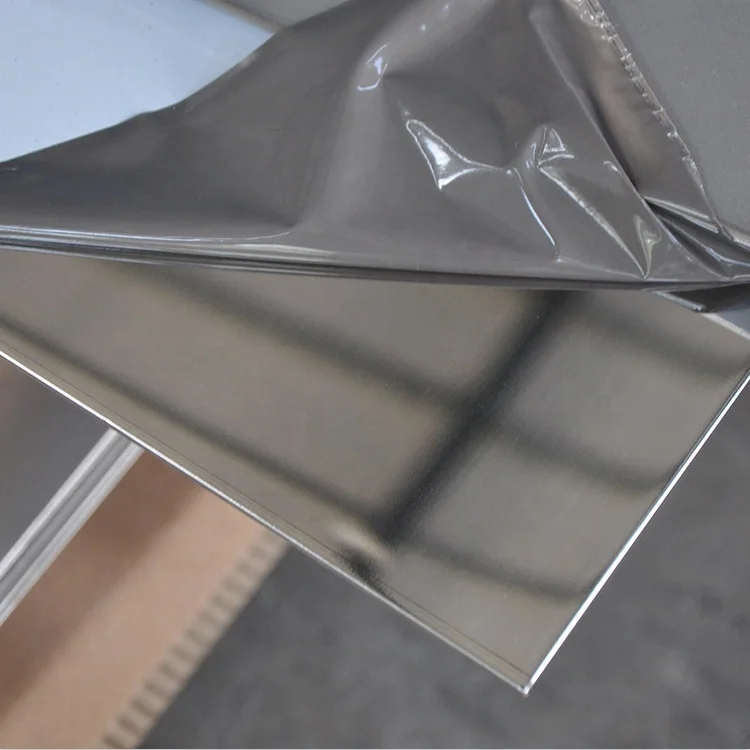

Smooth Surface:

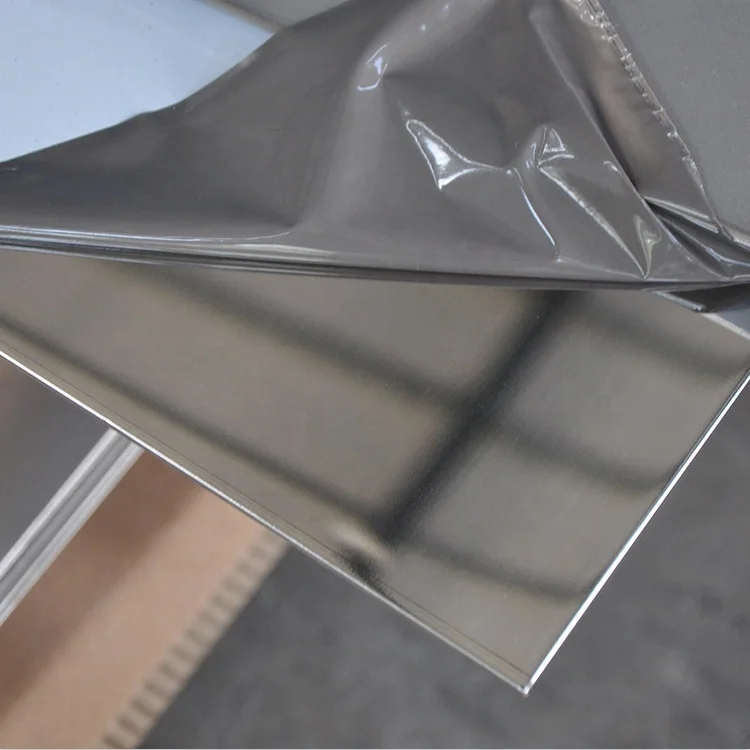

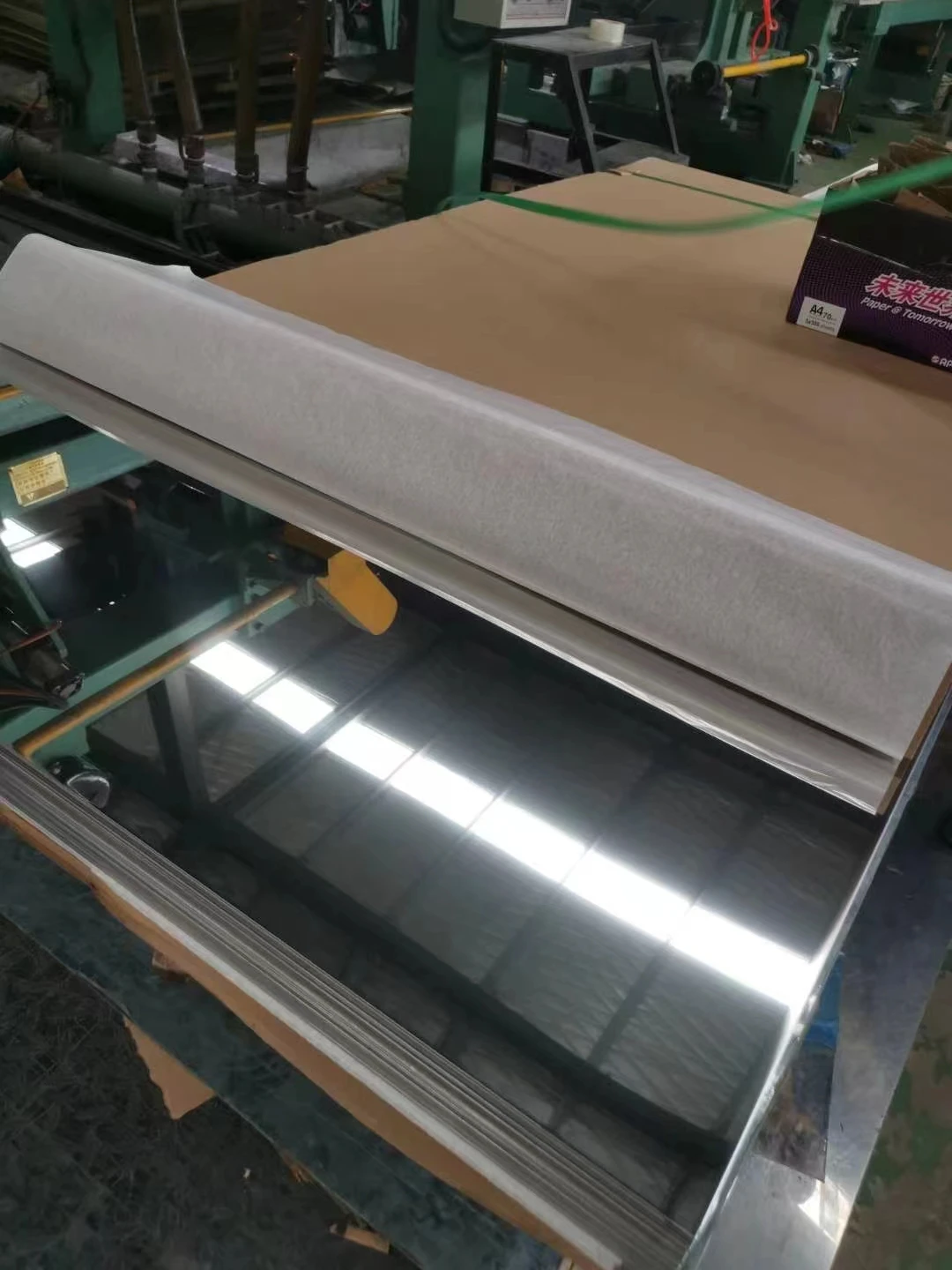

The smooth finish of these stainless steel sheets, available in various grades such as 2B, 2D, BA, NO.1, NO.4, NO.8, and mirror finish, adds aesthetic value and increases functionality. It is easy to etch, brush, or polish, making it suitable for architectural, decorative, and functional purposes.

Heat Resistance:

As an austenitic stainless steel, it is capable of withstanding high temperatures, making it ideal for engineering and manufacturing environments where elevated temperatures are common.

High Durability:

Stainless steel plates are known for their durability and ability to resist rust and corrosion, ensuring longevity and reliability even in the most demanding environments.

Versatile Sizes:

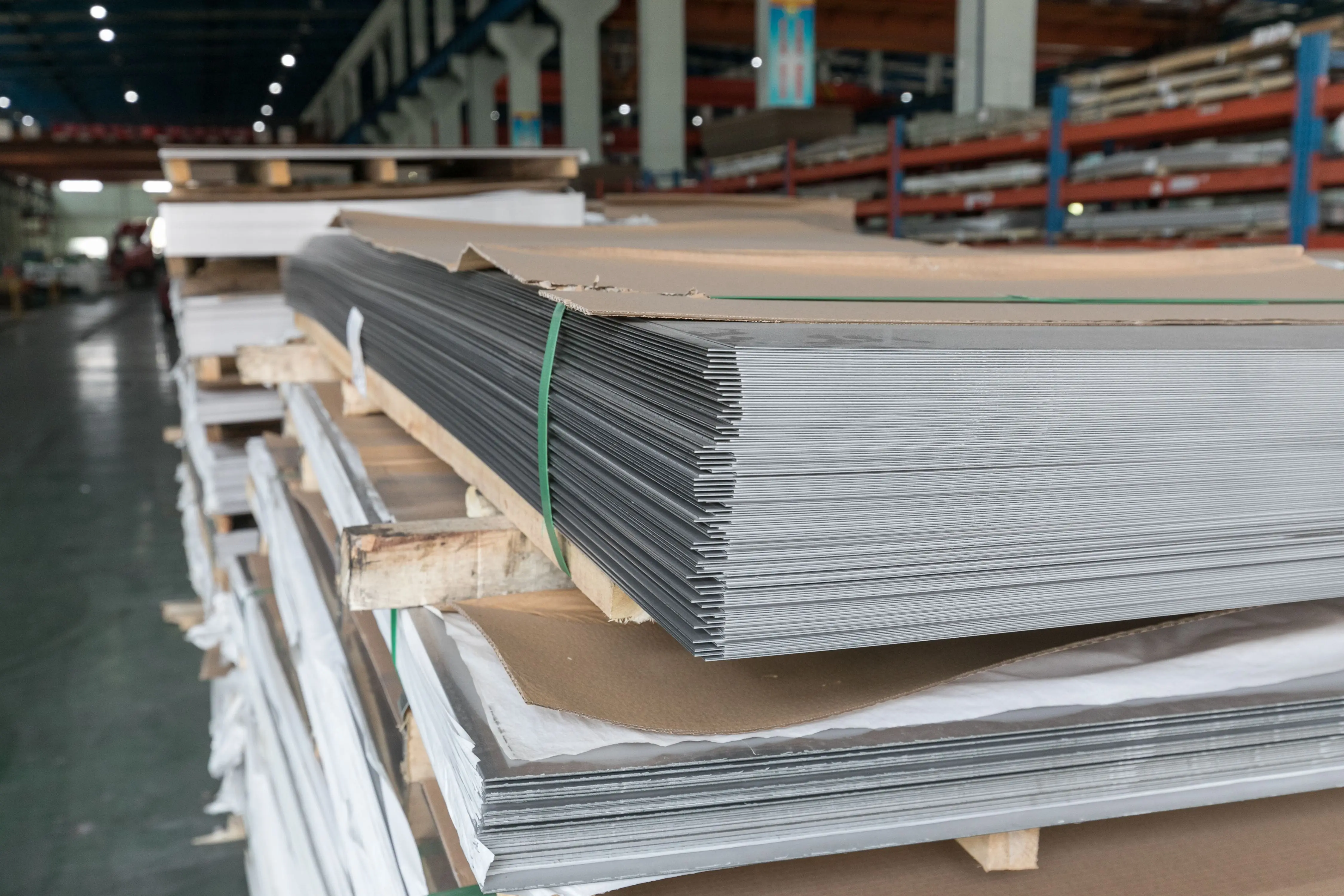

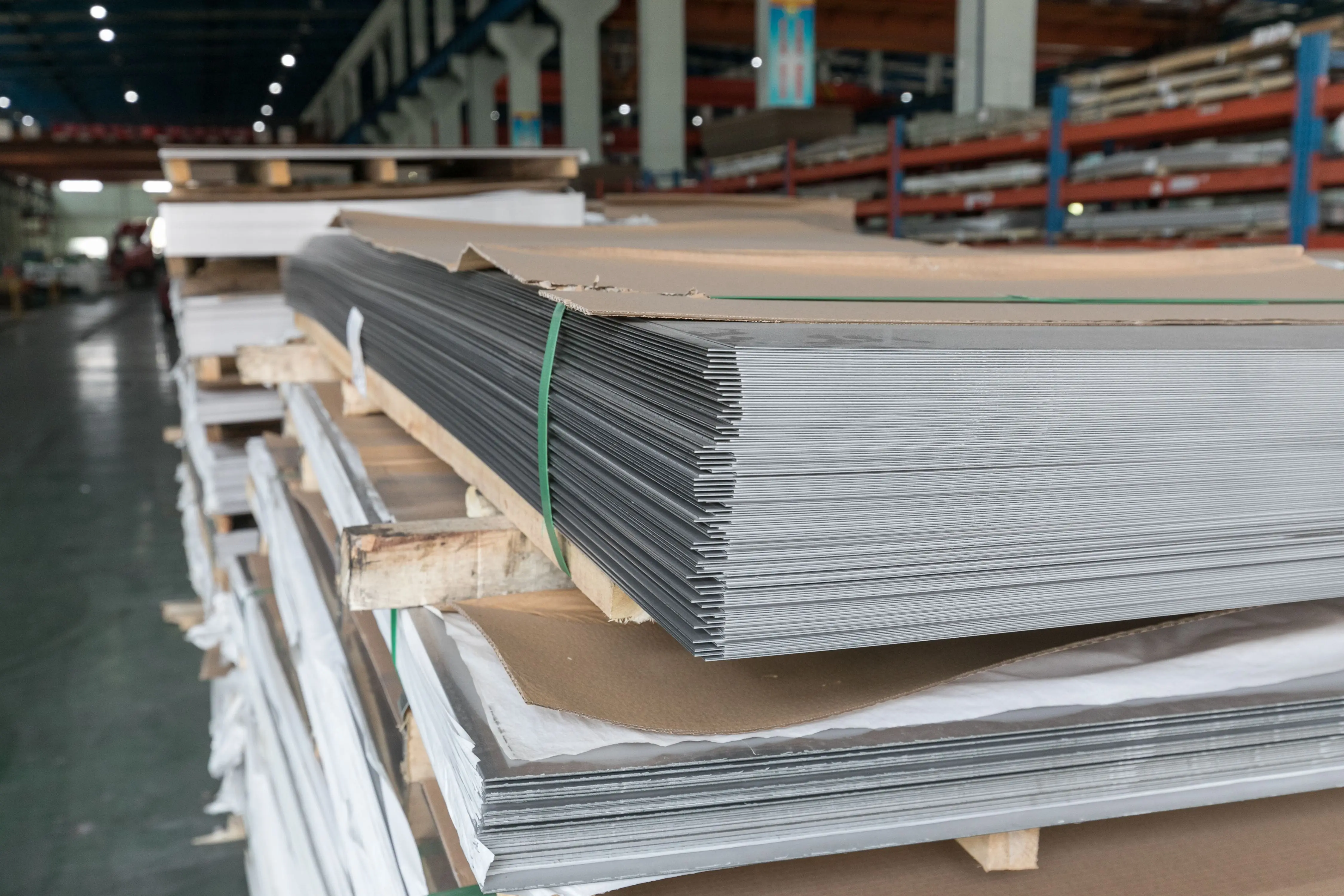

Available in custom-sized, oversized, standard-sized, and rectangular or square dimensions, these plates offer flexible solutions for various fabrication and structural needs.

2B,2D,BA,NO.1,NO.4,NO.8,8K,mirror,checkered,embossed,hair line,sand blast,brush. Multiple specifications are available.

The ASME A240 304N 304L Stainless Steel Sheet/Plate is a versatile material used in several industries for a broad range of applications. Some of the key uses include:

Architectural Applications: Stainless steel sheets are commonly used in architectural design for both functional and decorative purposes. With its polished and mirror finishes, it enhances the aesthetic appeal of buildings, walls, facades, and structural elements.

Automotive Manufacturing: In the automotive industry, stainless steel sheets are used for body panels, exhaust systems, and structural components due to their strength and corrosion resistance.

Marine and Shipbuilding: Due to its marine-grade qualities, the 304N/304L stainless steel is ideal for shipbuilding and offshore applications where corrosion resistance and durability are paramount.

Engineering & Industrial Manufacturing: This stainless steel is essential in manufacturing, engineering, and fabrication applications where components need to withstand wear and tear, high temperatures, and chemicals.

Infrastructure and Structural Uses: From structural framing to infrastructure support, the stainless steel plate is a critical material in construction and industrial sectors.

Food and Beverage Industry: Stainless steel is widely used in food processing equipment due to its non-reactive nature, ensuring hygiene and safety in industrial food production environments.

Metalworking: In metalworking, the sheet is used for crafting precision parts, tools, and custom-fabricated components.

The ASME A240 304N 304L Stainless Steel Sheet/Plate is simple to work with and can be cut, bent, welded, and shaped into various forms to suit your specific project needs. Below are some tips for operating and fabricating with this high-quality material:

Cutting: Stainless steel plates can be cut using various methods, including laser cutting, plasma cutting, water jet cutting, and mechanical cutting. The material is relatively easy to cut but requires proper equipment for precise and clean cuts.

Bending: The sheet can be easily bent or shaped by applying appropriate pressure using bending machines or manual tools. The high ductility of the 304N/304L stainless steel makes bending simple without compromising its strength.

Welding: TIG welding or MIG welding is commonly used to join stainless steel plates. Ensure that you use compatible filler materials for best results and maintain a clean welding environment to avoid defects.

Surface Treatment: The surface of stainless steel can be treated in several ways:

Polishing: To achieve a smooth, shiny surface, use polishing machines or abrasives for fine-grade finishes.

Brushing: A brushed finish is achieved by abrasive treatment, giving the material a sleek, modern look suitable for architectural and decorative uses.

Etching: For a unique and customized design, etching can be done on the surface of the stainless steel plates using acids or laser etching.

Storage and Handling: Store the stainless steel sheets in a dry, clean environment to avoid exposure to contaminants that could affect the surface quality. Handle with care to prevent scratches or other surface damage.

Q1: What is the difference between 304N and 304L stainless steel?

A1: The primary difference lies in the carbon content. 304N has a higher nitrogen content, improving its strength and toughness compared to 304L, which has lower carbon content, making it more resistant to intergranular corrosion. Both are austenitic stainless steels and offer similar corrosion resistance and weldability.

Q2: Can the ASME A240 304N 304L Stainless Steel Sheets be used in extreme temperatures?

A2: Yes, both 304N and 304L stainless steel can withstand high temperatures. However, 304N offers slightly better high-temperature resistance due to its higher nitrogen content, making it suitable for high-temperature industrial applications.

Q3: Are there different surface finishes available for these stainless steel plates?

A3: Yes, the ASME A240 304N 304L Stainless Steel Sheet/Plate is available in multiple surface finishes such as 2B, BA, NO.1, NO.4, NO.8, mirror, brushed, etched, and more. You can choose based on the aesthetic or functional needs of your project.

Q4: Can these stainless steel sheets be customized to specific sizes?

A4: Yes, we offer custom-sized plates in thin, thick, square, rectangular, and oversized dimensions, allowing you to tailor the material to your exact specifications.

Q5: What industries commonly use ASME A240 304N 304L Stainless Steel Sheets?

A5: This stainless steel is widely used across architectural, automotive, marine, engineering, fabrication, industrial, and construction industries due to its corrosion resistance, durability, and versatility.

The ASME A240 304N 304L Stainless Steel Sheet/Plate is an exceptional choice for industries that require high-quality, durable materials with excellent weldability, corrosion resistance, and aesthetic appeal. Whether you need large-sized, custom-sized, or standard-sized sheets, this stainless steel is the solution for your next project.

The ASME A240 304N 304L Stainless Steel Sheet/Plate is a high-quality, versatile material widely used in various industries. Known for its smooth surface, corrosion resistance, and excellent weldability, it is a critical component in modern industrial manufacturing. This stainless steel sheet is ideal for architectural, automotive, shipbuilding, engineering, construction, and infrastructure applications. Thanks to its ability to withstand harsh environments, it is used in a variety of industrial, marine, and metalworking projects.

Manufactured according to the ASME A240 standard, the 304N and 304L types of stainless steel sheets exhibit the best features of austenitic stainless steel, offering high toughness, plasticity, and weldability. These sheets are available in various finishes such as polished, brushed, etched, powder-coated, and more, offering versatility for both functional and decorative uses. Whether you need custom-sized, oversized, or standard-sized stainless steel plates, we can deliver tailored solutions for your requirements.

Product Advantage

The ASME A240 304N 304L Stainless Steel Sheet/Plate boasts several advantages that make it the go-to material for a wide range of applications:

Superior Corrosion Resistance:

The 304N and 304L types contain around 18% chromium and 8% nickel, which provide exceptional resistance to corrosion, particularly in environments exposed to moisture or harsh chemicals. This corrosion resistance makes it perfect for marine and industrial environments, where the material is exposed to challenging conditions.

Excellent Weldability:

With high weldability, this stainless steel plate is ideal for industries requiring strong and long-lasting welded connections, including shipbuilding, engineering, and metalworking.

Smooth Surface:

The smooth finish of these stainless steel sheets, available in various grades such as 2B, 2D, BA, NO.1, NO.4, NO.8, and mirror finish, adds aesthetic value and increases functionality. It is easy to etch, brush, or polish, making it suitable for architectural, decorative, and functional purposes.

Heat Resistance:

As an austenitic stainless steel, it is capable of withstanding high temperatures, making it ideal for engineering and manufacturing environments where elevated temperatures are common.

High Durability:

Stainless steel plates are known for their durability and ability to resist rust and corrosion, ensuring longevity and reliability even in the most demanding environments.

Versatile Sizes:

Available in custom-sized, oversized, standard-sized, and rectangular or square dimensions, these plates offer flexible solutions for various fabrication and structural needs.

2B,2D,BA,NO.1,NO.4,NO.8,8K,mirror,checkered,embossed,hair line,sand blast,brush. Multiple specifications are available.

The ASME A240 304N 304L Stainless Steel Sheet/Plate is a versatile material used in several industries for a broad range of applications. Some of the key uses include:

Architectural Applications: Stainless steel sheets are commonly used in architectural design for both functional and decorative purposes. With its polished and mirror finishes, it enhances the aesthetic appeal of buildings, walls, facades, and structural elements.

Automotive Manufacturing: In the automotive industry, stainless steel sheets are used for body panels, exhaust systems, and structural components due to their strength and corrosion resistance.

Marine and Shipbuilding: Due to its marine-grade qualities, the 304N/304L stainless steel is ideal for shipbuilding and offshore applications where corrosion resistance and durability are paramount.

Engineering & Industrial Manufacturing: This stainless steel is essential in manufacturing, engineering, and fabrication applications where components need to withstand wear and tear, high temperatures, and chemicals.

Infrastructure and Structural Uses: From structural framing to infrastructure support, the stainless steel plate is a critical material in construction and industrial sectors.

Food and Beverage Industry: Stainless steel is widely used in food processing equipment due to its non-reactive nature, ensuring hygiene and safety in industrial food production environments.

Metalworking: In metalworking, the sheet is used for crafting precision parts, tools, and custom-fabricated components.

The ASME A240 304N 304L Stainless Steel Sheet/Plate is simple to work with and can be cut, bent, welded, and shaped into various forms to suit your specific project needs. Below are some tips for operating and fabricating with this high-quality material:

Cutting: Stainless steel plates can be cut using various methods, including laser cutting, plasma cutting, water jet cutting, and mechanical cutting. The material is relatively easy to cut but requires proper equipment for precise and clean cuts.

Bending: The sheet can be easily bent or shaped by applying appropriate pressure using bending machines or manual tools. The high ductility of the 304N/304L stainless steel makes bending simple without compromising its strength.

Welding: TIG welding or MIG welding is commonly used to join stainless steel plates. Ensure that you use compatible filler materials for best results and maintain a clean welding environment to avoid defects.

Surface Treatment: The surface of stainless steel can be treated in several ways:

Polishing: To achieve a smooth, shiny surface, use polishing machines or abrasives for fine-grade finishes.

Brushing: A brushed finish is achieved by abrasive treatment, giving the material a sleek, modern look suitable for architectural and decorative uses.

Etching: For a unique and customized design, etching can be done on the surface of the stainless steel plates using acids or laser etching.

Storage and Handling: Store the stainless steel sheets in a dry, clean environment to avoid exposure to contaminants that could affect the surface quality. Handle with care to prevent scratches or other surface damage.

Q1: What is the difference between 304N and 304L stainless steel?

A1: The primary difference lies in the carbon content. 304N has a higher nitrogen content, improving its strength and toughness compared to 304L, which has lower carbon content, making it more resistant to intergranular corrosion. Both are austenitic stainless steels and offer similar corrosion resistance and weldability.

Q2: Can the ASME A240 304N 304L Stainless Steel Sheets be used in extreme temperatures?

A2: Yes, both 304N and 304L stainless steel can withstand high temperatures. However, 304N offers slightly better high-temperature resistance due to its higher nitrogen content, making it suitable for high-temperature industrial applications.

Q3: Are there different surface finishes available for these stainless steel plates?

A3: Yes, the ASME A240 304N 304L Stainless Steel Sheet/Plate is available in multiple surface finishes such as 2B, BA, NO.1, NO.4, NO.8, mirror, brushed, etched, and more. You can choose based on the aesthetic or functional needs of your project.

Q4: Can these stainless steel sheets be customized to specific sizes?

A4: Yes, we offer custom-sized plates in thin, thick, square, rectangular, and oversized dimensions, allowing you to tailor the material to your exact specifications.

Q5: What industries commonly use ASME A240 304N 304L Stainless Steel Sheets?

A5: This stainless steel is widely used across architectural, automotive, marine, engineering, fabrication, industrial, and construction industries due to its corrosion resistance, durability, and versatility.

The ASME A240 304N 304L Stainless Steel Sheet/Plate is an exceptional choice for industries that require high-quality, durable materials with excellent weldability, corrosion resistance, and aesthetic appeal. Whether you need large-sized, custom-sized, or standard-sized sheets, this stainless steel is the solution for your next project.