- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Material: | |

|---|---|

| Shape: | |

| Thickness: | |

| Length: | |

| Purling: | |

| Main frame : | |

| Availability: | |

| Quantity: | |

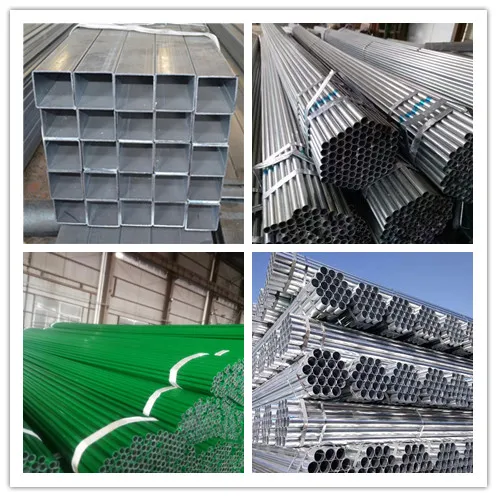

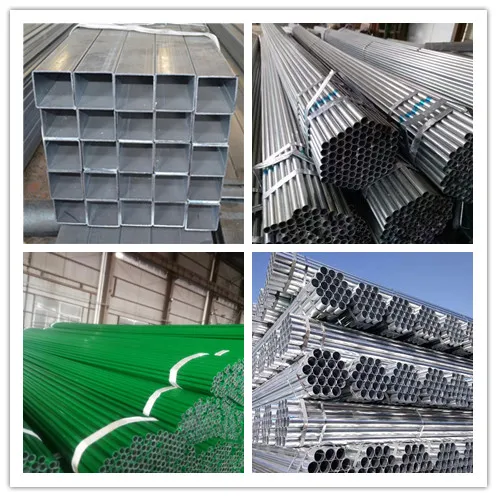

We provide various thickness and diameters of high-quality galvanized steel pipes, including seamless pipes, welded pipes, square pipes, round pipes, cold-rolled and hot-rolled pipes, etc. Mainly used in the manufacture of construction accessories, transportation pipelines, bridges and railways, etc.

1.Galvanized steel pipe has the following production steps:

Black parts inspection→hanging→degreasing→rinsing→pickling→cleaning→dipping flux→hot air drying→hot-dip galvanizing→cooling→passivation and rinsing→unloading→inspection, trimming→packaging, storage, transportation .

2.

Hot-dip galvanized steel pipes are widely used in construction, machinery, coal mines, chemicals, electric power, railway vehicles, automobile industry, highways, bridges, containers, sports facilities, agricultural machinery, petroleum machinery, prospecting machinery and other manufacturing industries.

3.

Galvanized steel pipe is a welded steel pipe with a hot-dip galvanized or electro-galvanized layer on the surface. Galvanizing can increase the corrosion resistance of steel pipes and prolong the service life. Galvanized pipes have a wide range of uses. In addition to being used as pipeline pipes for general low-pressure fluids such as water, gas, etc., they are also used as oil well pipes and oil pipes in the petroleum industry, especially in offshore oil fields, oil heaters in chemical coking equipment, and condensation cooling. Pipes for septic tank, coal distillation washing oil exchanger, trestle pipe piles, supporting frame pipes for mine tunnels, etc.

We provide various thickness and diameters of high-quality galvanized steel pipes, including seamless pipes, welded pipes, square pipes, round pipes, cold-rolled and hot-rolled pipes, etc. Mainly used in the manufacture of construction accessories, transportation pipelines, bridges and railways, etc.

1.Galvanized steel pipe has the following production steps:

Black parts inspection→hanging→degreasing→rinsing→pickling→cleaning→dipping flux→hot air drying→hot-dip galvanizing→cooling→passivation and rinsing→unloading→inspection, trimming→packaging, storage, transportation .

2.

Hot-dip galvanized steel pipes are widely used in construction, machinery, coal mines, chemicals, electric power, railway vehicles, automobile industry, highways, bridges, containers, sports facilities, agricultural machinery, petroleum machinery, prospecting machinery and other manufacturing industries.

3.

Galvanized steel pipe is a welded steel pipe with a hot-dip galvanized or electro-galvanized layer on the surface. Galvanizing can increase the corrosion resistance of steel pipes and prolong the service life. Galvanized pipes have a wide range of uses. In addition to being used as pipeline pipes for general low-pressure fluids such as water, gas, etc., they are also used as oil well pipes and oil pipes in the petroleum industry, especially in offshore oil fields, oil heaters in chemical coking equipment, and condensation cooling. Pipes for septic tank, coal distillation washing oil exchanger, trestle pipe piles, supporting frame pipes for mine tunnels, etc.